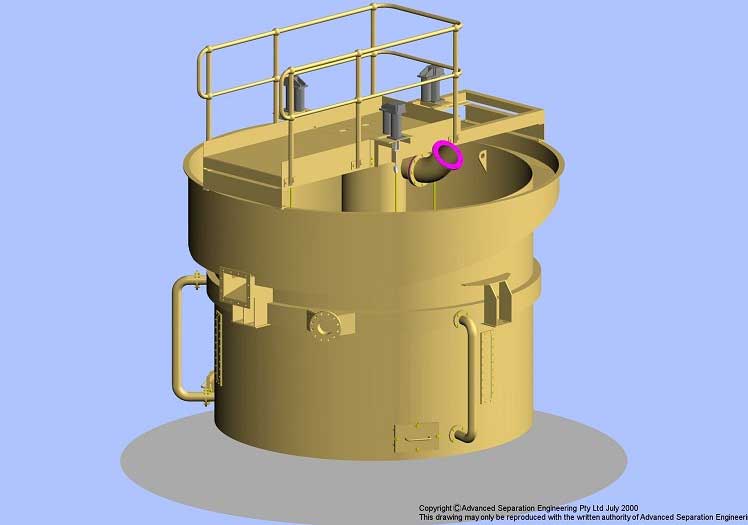

KRS-TBS Hydrosizer(TBS)

² General Description

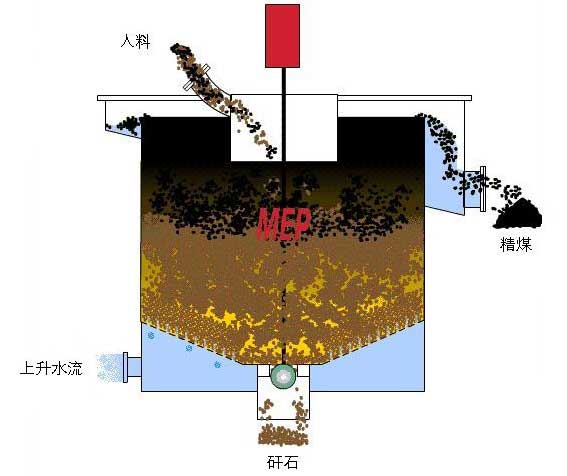

TBS is a hindered settling separator, using upward current water to create a column of teeter in the vessel. Slurry feed enters into the unit by means of a tangential direction. The smaller material and lighter particles flow into the overflow launder by the effect of up current water and the heavier particles, which concentrate at the bottom of the cell, are discharged through the spigot valve(s).

² Typical applications include:

Ø Classification of minus 5 mm sands.

Ø Beneficiation of fine coal.

Ø Removal of pyrites from minus 5 mm coal.

Ø Removal of lignite/peat from sand.

Ø Removal of heavy contaminants from sand.

Ø Ore dressing including: tin, lead and zinc.

² Principle of Operation

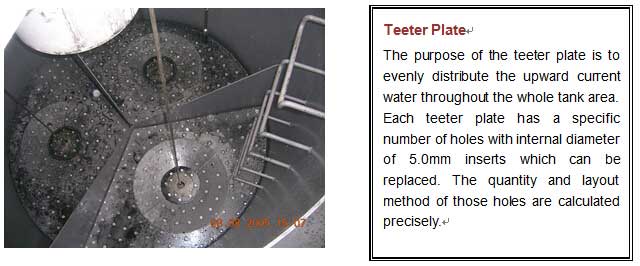

TBS is a hindered settling separator, using upward current water to create a column of teeter in the vessel. The teeter bed inside TBS tank can be regarded as medium self-generation bed and separate the minus 5mm particles into two size groups or separate by specific gravity based on the different material density. The up current water is introduced into the pressure tank at a certain pressure and velocity passing through the teeter bed and distributed into the bottom of TBS evenly. When the solids are fed into TBS, they are starting being separated into two groups that is affected by the up current water and the larger material and heavier particles are concentrated onto the bottom of tank, while the smaller material and lighter particles are flew to the top of tank.

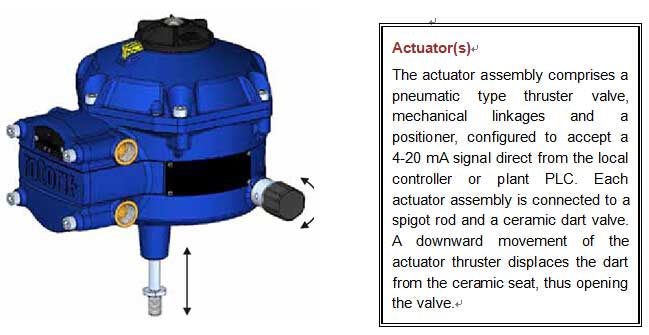

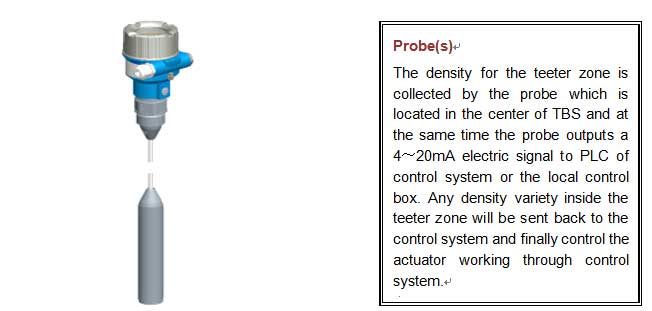

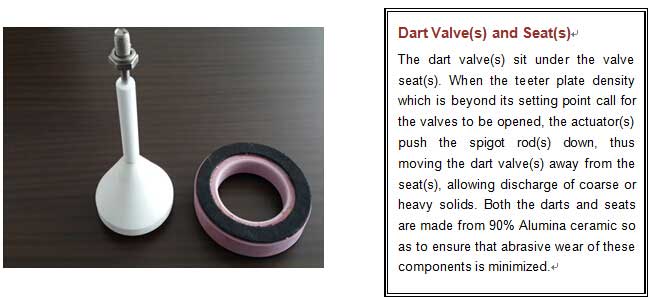

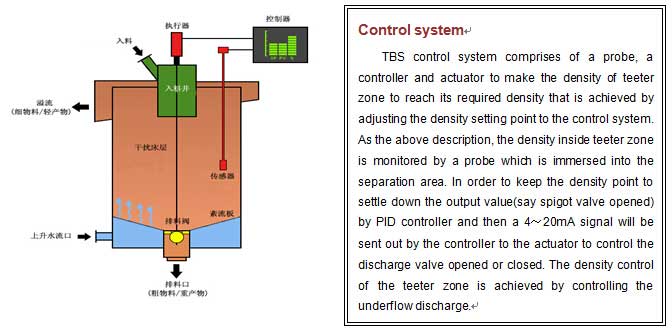

Along with the material feed continuously, smaller material and lighter particles overflow to the overflow launder, the high density material is discharged by the spigot valve which is controlled by a PID controller. The density probe immerses into the proper location inside the teeter zone and monitors the internal density of tank continuously. As the density reach or above the setting point, the controller will send out a 4~20mA signal to the air actuator that caused the actuator working and spigot valve opened to discharge until the density recover to the setting point, then the spigot valve is closed. Discharge valve is opened by means of PID controller to keep the setting density value of teeter zone steadily inside the tank. The stroke for air actuator is approximately 40mm, the actuator works smoothly within this range, at the same time discharge valve will move under its control.

² TBS Components

² Application Range

Ø Efficient alternative for fine coal processing

Ø Replace other fine coal separation device, such as Spiral, Heavy medium cyclone with

small diameter and so on.

Ø Re-separate for spiral clean coal

Ø Recover fine coal from flotation tailings

² Features

Ø Feeding size between 4–0.1mm achieves good results in separation,size ratio of 4:1 preferred;

Ø Effective separating density is 1.4–1.9;

Ø Separating density is adjustable;

Ø Completely automatic control, no operator needed;

Ø Flexible of feeding coal quality;

Ø No complex feed distributed system;

Ø Small space needed and long service life;

Ø No heavy media and chemical reagent needed;

Ø No power consumption;